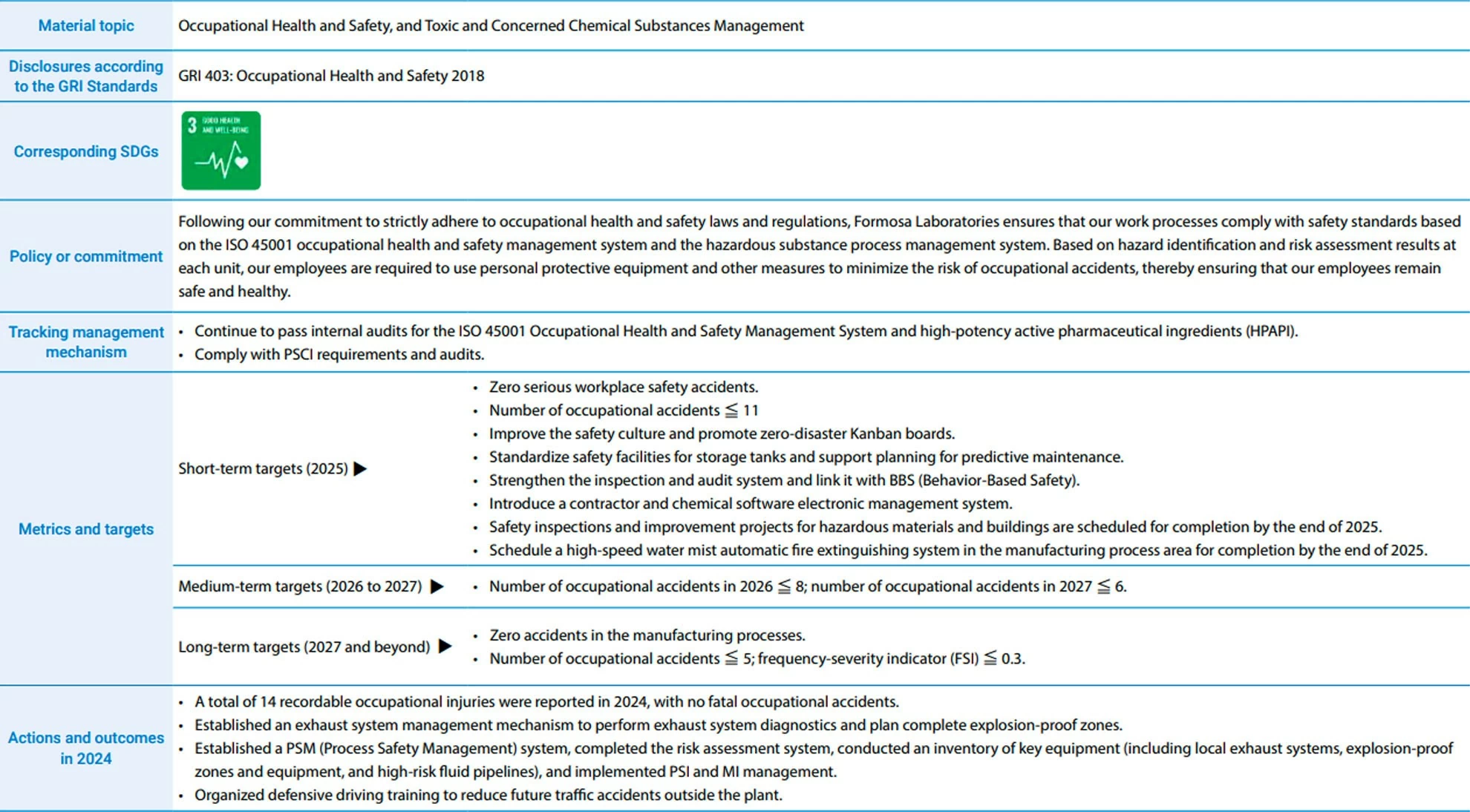

Management of material topics "Toxic and Concerned Chemical Substances Management" and "Occupational Health and Safety" at Formosa Laboratories in 2024

Occupational Health and Safety Management

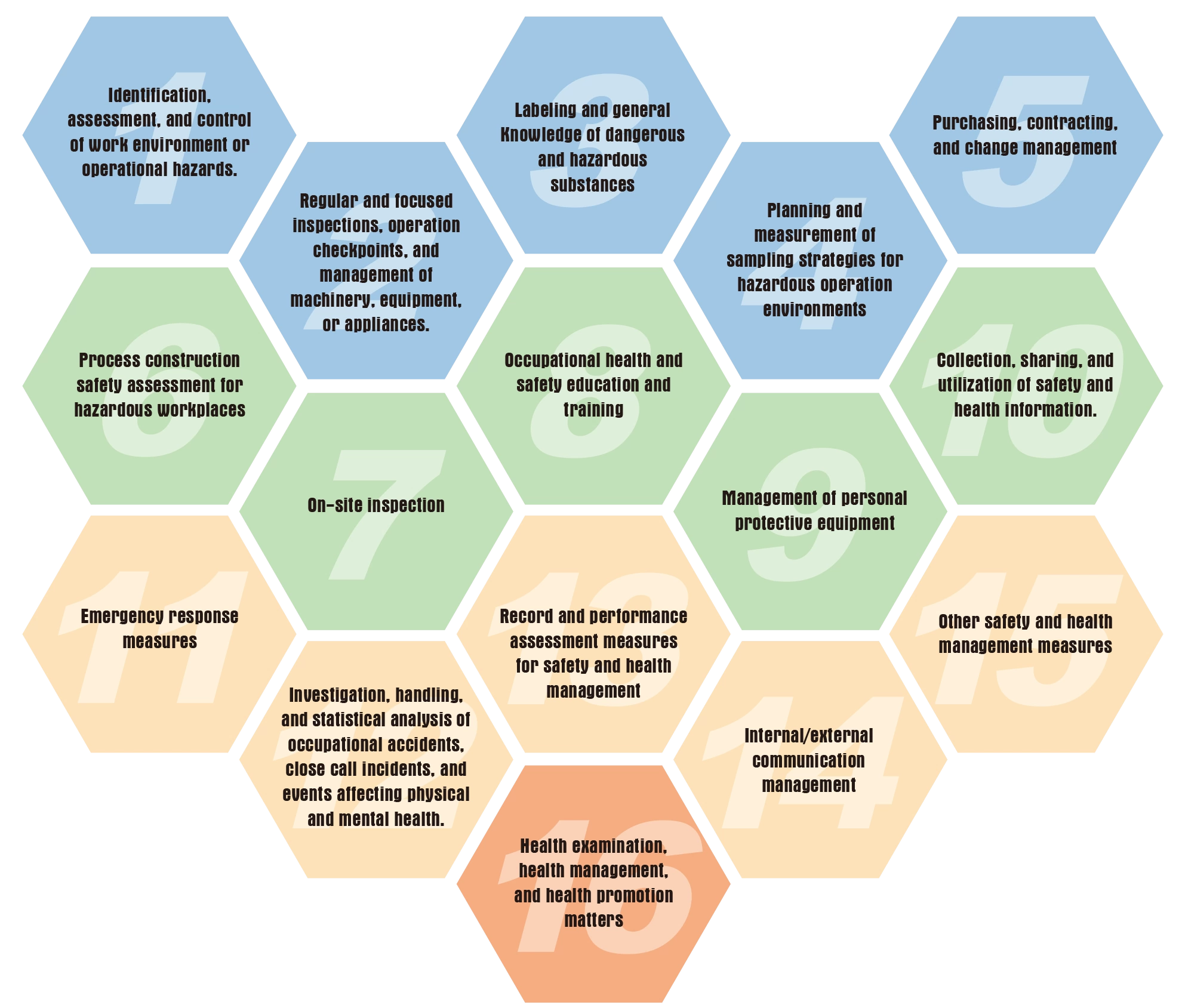

Formosa Laboratories has implemented various occupational safety programs and adopted ISO occupational health and safety management standards and requirements to regulate all workers, customized synthesis and mass production of APIs, and specialty chemicals at our Luzhu Plant and Luzhu No.2 Plant, covering 100% of our workforce. Additionally, a total of 16 occupational health and safety management programs have been developed in accordance with the relevant laws regulations, which are detailed on Formosa Laboratories' official website.

Formosa Laboratories has established the Occupational Health and Safety Committee in accordance with the Regulations Governing Occupational Health and Safety Management. The committee is made up of the workplace safety unit, top-level managers from various departments, and labor representatives from labor-management meetings. It includes 20 members: one medical professional, 1 occupational health and safety staff member, 11 department heads, and 7 labor representatives, who make up more than one-third of the total membership. The committee's role is to enhance the occupational health and safety environment through planning and action. They meet quarterly. In 2024, the committee's resolutions included standardizing procedures for storage tank safety facilities to support predictive maintenance planning and promoting zero-accident signage.

Formosa Laboratories' 16 Major Items of Occupational Safety and Health Management Program

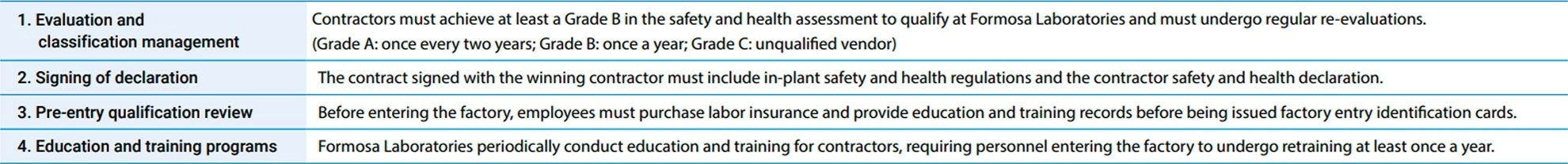

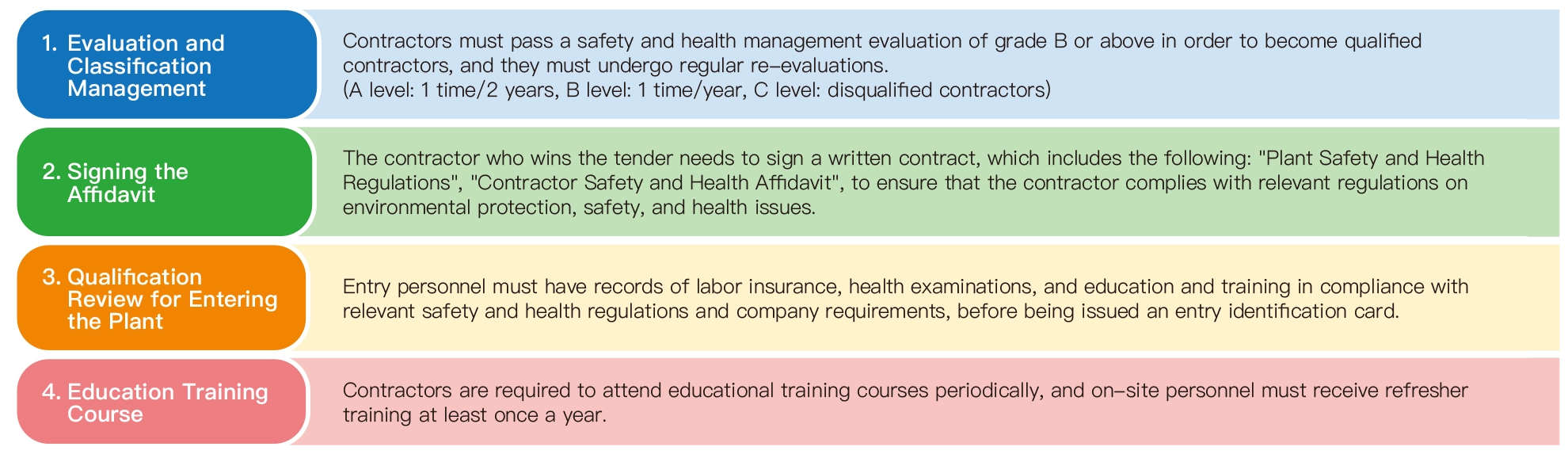

Contractor Occupational Health and Safety Management

According to the contractor management program at Formosa Laboratories, we not only hold contractor toolbox meetings from time to time, but also implement pre-entry safety and health training, audit, and penalties for violations. Formosa Laboratories implements the following measures to control contractors and provide them with the relevant guidance :

Occupational Safety and Health Committee

To protect the rights and interests of employees, the Company has established an Occupational Safety and Health Committee in accordance with the requirements of the "Regulations on Occupational Safety and Health Management", which is composed of the occupational safety and health unit, the first-level supervisors of each department, and the labor representatives of the labor-management meeting. The Committee comprises a total of 20 members, including 1 medical personnel, 1 occupational safety and health personnel, 11 supervisory and commanding personnel from each department, and 7 labor representatives. The labor representatives make up more than one-third of the total.

The Occupational Safety and Health Committee is responsible for improving the occupational safety and health environment, enhancing the level of safety and health management, and achieving safety management goals through planning, implementation, and assessment. A safety and health committee meeting is held quarterly to discuss topics including the management of occupational accidents, education training and campaign, environmental monitoring reports, employee health protection and health monitoring analysis, implementation results of health promotion, fire alarm management, emergency response management, safety and health management of contracted businesses, automatic inspection management, audit inspections, application for the operation of toxic chemicals operation and management of controlled chemicals registration, safety and health self-evaluation management, and management review reports of occupational safety and health management systems.

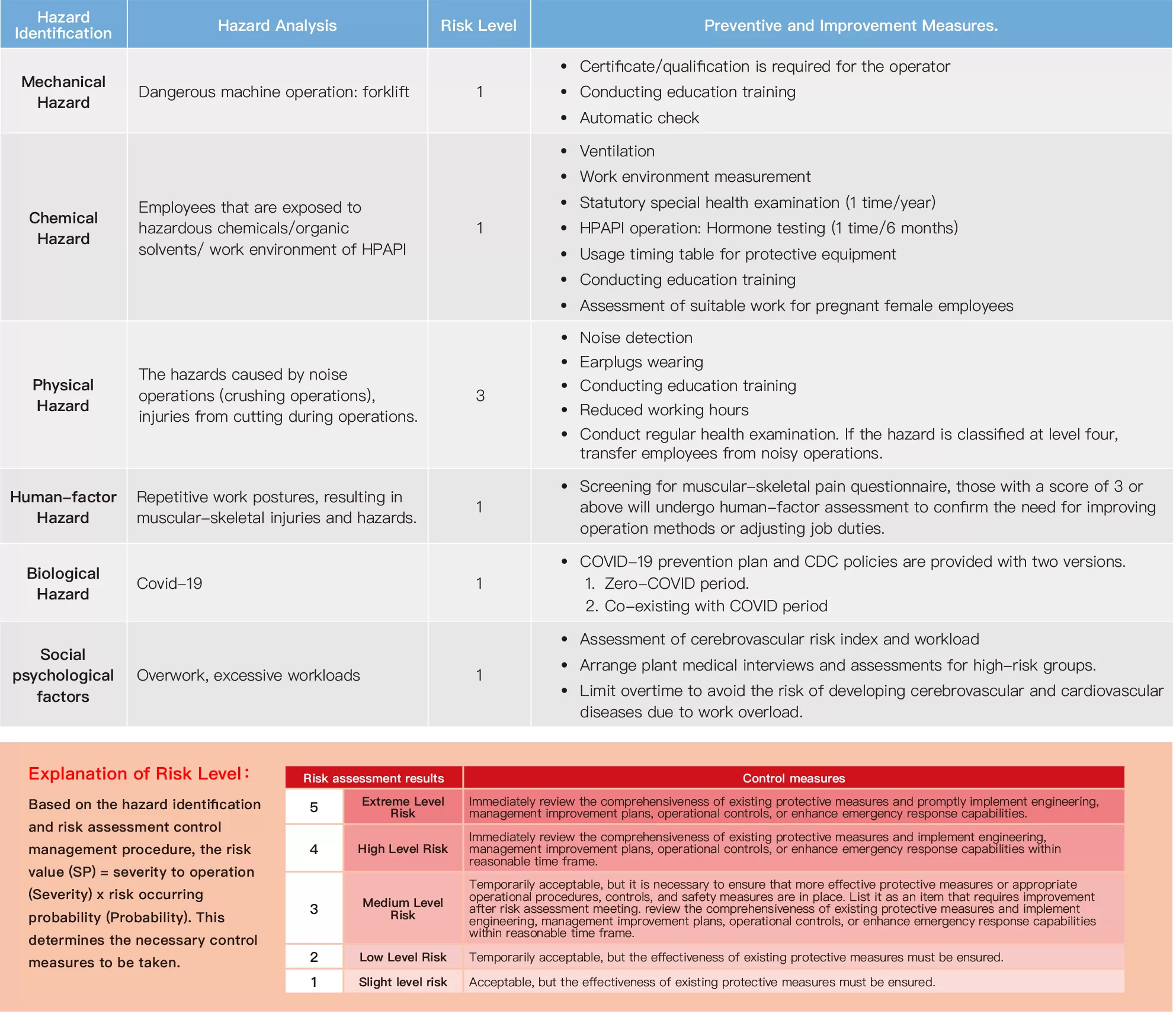

Hazard Identification and Risk Prevention

We also review and update the schedule for using protective equipment each year, require personnel to wear appropriate protective gear according to the schedule, and perform automatic machinery inspections to ensure continued effectiveness of safety measures. For more details on hazard identification, risk assessments, and improvement measures, please visit our official website.

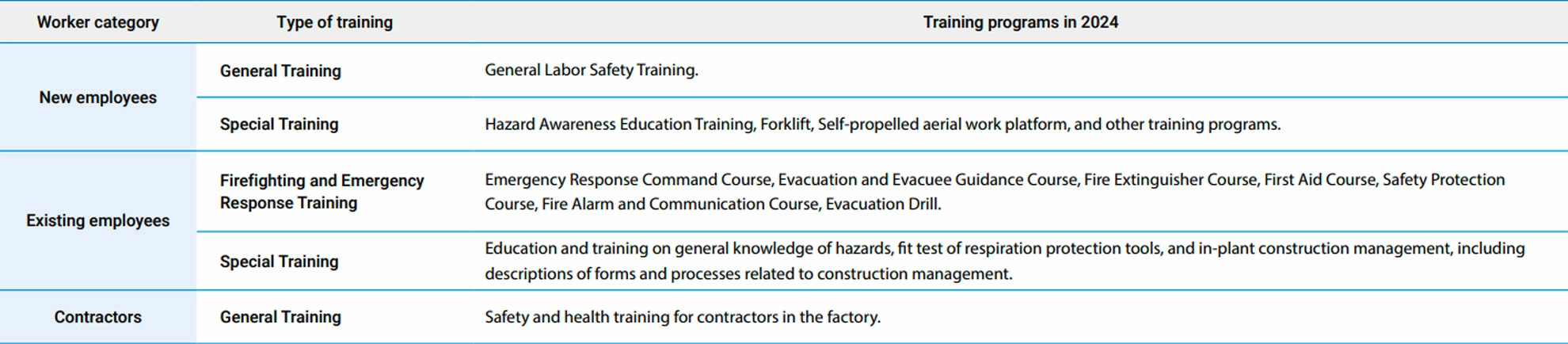

Occupational Health and Safety Education and Training

In addition to implementing emergency response measures, Formosa Laboratories regularly conducts workplace safety training for new employees, contracted workers, and provides refresher training for existing staff. We also create an emergency response plan every year.

In 2024, we offered specialized training for units and personnel involved in higher-risk operations or chemical handling. Additionally, we enhanced team-based response drills, with each team performing regional joint defense exercises. Given the recent increase in traffic accidents among employees, we introduced new defensive driving courses to help reduce the chances of such incidents.

▼Occupational health safety and training for employees at Formosa Laboratories in 2024

Occupational Hazard Risk Management

Based on the record of occupational accident incidents, the Company assists various units in conducting hazard identification and risk assessment to establish risk levels. Currently, the highest potential risk is the physical hazard generated by noise operations. In addition to strengthening education and training and providing protective equipment, we also track employees' physical health through regular health examination to control and prevent occupational diseases. For other potential hazards in the process of process operations, including improper injury from mechanical operations and hazards from chemical use, we also enhance relevant special education and training for designated operating units and engineering personnel, setting management goals and tracking regularly. For example, we arrange advanced emergency drills, fire, and chemical disaster response drills once a year.

Also, we annually review and update the timing table for the use of protective equipment. The timing table is used as a guide for wearing appropriate protective equipment to conduct automatic mechanical equipment inspections and manage hazardous mechanical equipment to continuously ensure the effectiveness of protective measures.

Formosa Laboratories Self-rescue Team

Formosa Laboratories has established a self-rescue team to improve the emergency response capabilities of all employees. The goal of the self-rescue team is to protect our employees' lives, reduce disaster-related losses,and ensure the company can respond quickly during emergencies. We hold relevant training and meetings every month and also participate in nowarning mission training organized by government agencies. Through ongoing training, practical exercises, and the acquisition of necessary disaster relief equipment, we aim to enhance the professionalism and teamwork of the self-rescue team, ensuring we can provide effective emergency support in any unforeseen situation, safeguarding everyone's safety and maintaining the company's stability.

▼Unannounced nationwide joint response training organized by the Environmental Protection Bureau

▼ In-plant chemical disaster response drill

Hazard Identification, Analysis, Prevention, and improvement measures in the Occupational Safety and Health Management of Formosa Laboratories.

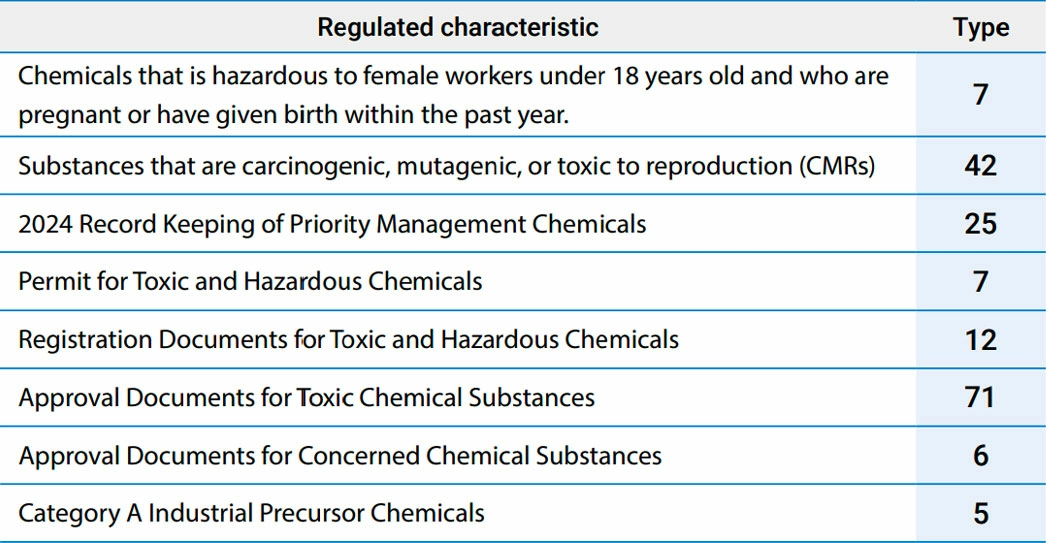

Hazardous Substances Management

The operation of Formosa Laboratories' hazardous substances process management system includes verifying the storage of raw materials, reviewing the part number of finished products, assessing whether the chemicals are regulated by law and classifying them, and establishing a chemical inventory while implementing systematic management and control based on the hazards and risks of different chemicals and relevant regulatory requirements. To minimize the risk of direct contact with chemicals or hazards to our personnel, Formosa Laboratories has installed local exhaust ventilation devices and established a schedule for the use of personal protective equipment based on the results of hazard identification and risk assessment for each unit, strengthening the enforcement of personal protective measures.

▼Regulated Categories of Hazardous Substances

Additionally, Formosa Laboratories regularly updates the List of Chemicals Hazardous to Pregnant Workers at All Factories and identifies the types and quantities of substances that pose health risks or are carcinogenic, mutagenic, or toxic to reproduction (CMRs). We also involve factory nurses and unit supervisors to conduct fitness-for-duty assessments and provide refresher training on hazard awareness to ensure our staffs are equipped with safety knowledge and emergency response skills.

Contractor Occupational Health and Safety Management Measures

Based on the Company's 16 occupational safety and health management plans, we conducted contractor toolbox meetings and organization of agreements, carried out contractor safety audits and imposed penalties for violations, developed contractor emergency response plans, implemented safety permits and hazardous operations measures for contractor, revised contractor safety and health management regulations, and provided contractor safety education and training for onsite entry. The following are the four main areas of control and guide for contractors.

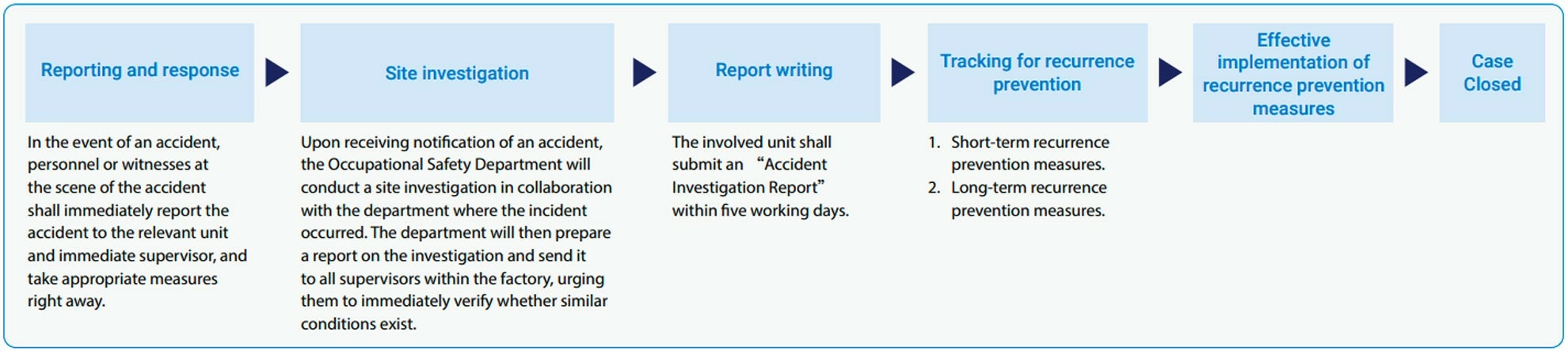

Accident Response Management

To effectively prevent workplace accidents and reduce the risk of recurrence, we have established the CO-328 Accident Emergency Response and Reporting Procedure. In addition, in accordance with Article 18 of the Occupational Safety and Health Act, Formosa Laboratories ensures workers' right to withdraw from potentially hazardous work environments. If workers believe their safety is at risk, they have the right to leave the work site. In the event of an uncontrollable accident or imminent injury, each building will implement emergency response measures, and, if necessary, activate the factory evacuation plan, prioritizing worker safety.

We conduct autonomous plant fire (chemical) disaster drills every year to train response team members and ensure they master relevant skills. Additionally, at least one preannounced emergency measures test is organized annually to assess the effectiveness of practical operations and the emergency response plan. In 2024, the emergency drills included a full-plant evacuation, a plant fire (chemical) disaster drill, and escape drills for earthquakes and power failures. Through these drills, employees are expected to respond quickly and appropriately when relevant accidents occur.

At the same time, we hold review meetings after incidents or drills to document relevant deficiencies. We continuously review and update response procedures and measures annually, and check emergency response facilities and plan for the necessary emergency and first-aid equipment (e.g., firefighting tools, public address systems, fire extinguishers, stretchers, etc.). We perform regular monthly maintenance and inspections to ensure these devices remain effective.

▼Accident reporting and handling process

Investigation Procedures for Occupational Accidents at Formosa Laboratories

| Accidents Occurrence |

|

|---|---|

| Investigation of the cause of the incident. |

|

| Review and Improvement Measures for the Incident | Proposed by the unit that the accident occurs, monitor and track improvement measures based on the accident investigation and analysis report. These measures shall be implemented until improvements are completed, and a comprehensive review and assessment shall be conducted to prevent similar incidents from happening again. |

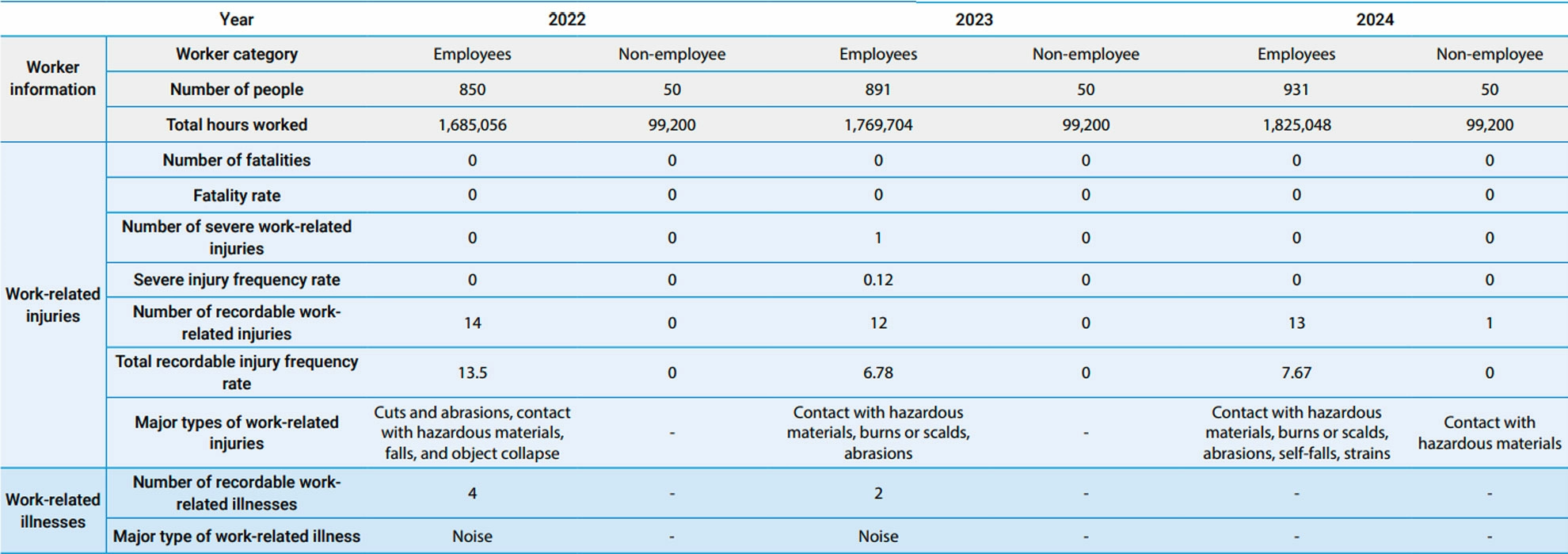

Statistics on Work-related Injuries and Illnesses

In 2024, Formosa Laboratories reported 14 recordable work-related injuries, with "contact with hazardous materials" being the most common type, accounting for six cases. No severe injuries or fatalities occurred. Work-related illness data are based on employees classified under Level 4 health management, according to specific health exams. No work-related illnesses were reported.

▼ Statistics on work-related injuries and illnesses among workers at Formosa Laboratories over the past three years

Note:

- Work-related injuries refer to accidental injuries that happen when workers are performing their duties or are at the workplace. Statistics on such injuries do not include “commuting accidents” that occur while traveling to and from work.

- The number of employees is the average of the reported monthly occupational accidents throughout the year. The number of non-employee workers includes the total of dispatched and resident contract workers, plus an average of 10 to 30 general construction contract workers, totaling about 50 people each month.

- Total hours worked refers to the total number of hours worked by all workers for the entire year. Specifically, the number of hours worked by employees is determined based on the number of actual hours worked and the number of hours worked overtime, whereas the number of hours worked by non-employee workers is estimated using the following formula: 8 hours per day × 50 people per day × Number of working days throughout the year.

- Severe work-related injuries refer to injuries (other than fatalities) that cause disability or prevent a return to the pre - injury level of health within six months.

- Other recordable work-related injuries refer to injuries (excluding commuting injuries), regardless of whether they involve work-related injury leave. Meanwhile, the number of recordable work-related illnesses is determined based on the count of workers under Level 4 health management, according to special health examination results. However, no fatal cases were reported at Formosa Laboratories. Details about workrelated injuries among non-employee workers were omitted from this report because the related information was difficult to obtain.

- Fatality rate = Number of fatalities caused by work-related injuries × 1,000,000 ÷ Total hours worked.

- Severe work-related injury rate = Number of severe work-related injuries × 1,000,000 ÷ Total hours worked.

- Total recordable injury frequency rate (TFIFR) = Number of recordable work-related injuries (including the number of severe work-related injuries, the number of fatalities, and the number of other recordable workrelated injuries) × 1,000,000 ÷ Total hours worked.

- Method for calculating rates in Items 6 to 8 : Calculated to two decimal places.

- The 1,000,000-hour-worked rate refers to the number of work-related injuries per 500 full-time workers within one year, based on the assumption that full-time workers work 2,000 hours a year.

- Measures to reduce noise-induced occupational diseases: Reduce exposure time, adjust work schedules, and implement time management for exposure.

▼Statistics on disabling injury frequency and severity rates among workers at Formosa Laboratories over the past three years

| Year | Worker category | Number of work days lost due to disabling injuries | Disabling injury frequency rate (FR) | Disabling injury severity rate (SR) | Frequency-severity indicator (FSI) |

|---|---|---|---|---|---|

| 2022 | Employees | 13.50 | 8.31 | 8 | 0.26 |

| Non-employee | 0 | 0 | 0 | 0 | |

| 2023 | Employees | 68.85 | 6.78 | 38 | 0.51 |

| Non-employee | 0 | 0 | 0 | 0 | |

| 2024 | Employees | 36.3 | 7.67 | 19 | 0.39 |

| Non-employee | 0 | 0 | 0 | 0 |

Note:

- The number of workdays lost is calculated by dividing the number of hours workers are unable to work by 8 hours, based on work-related accident or injury leave ( ≦ 1 hour) taken by workers, excluding sick leave and menstrual leave.

- Disabling injury frequency rate (FR) - Number of disabling injuries × 1,000,000 ÷ Total hours worked (calculated to two decimal places without rounding).

- Disabling injury severity rate (SR) = Number of workdays lost due to disabling injuries × 1,000,000 ÷ Total hours worked (calculated to two decimal places without rounding).

- Frequency-severity indicator (FSI) = √ [(FR × SR) ÷ 1,000] (calculated to two decimal places, with the third decimal place rounded up).

- Restatement of information: The original disability injury severity rates (SR) for 2022-2023 were 8.01 and 38.90. These values have been corrected by rounding to the nearest integers, as per the annotated formula.

Health Examination

Formosa Laboratories performs annual health check-ups for all employees, including general health screenings and specialized exams for those involved in hazardous operations.

Additionally, employees working with the HPAPI manufacturing process undergo hormone testing every six months. We also implement tiered health management in accordance with legal requirements. Based on the results, factory nurses and medical specialists provide health education and follow-up care, and may perform on-site assessments of suspected workrelated illnesses when necessary.

Employees classified as Level 3 or higher in the special health examination results will undergo ongoing monitoring and reclassification. Employees at Level 4 will receive work hazard control measures and relevant management actions, with consultation and guidance from medical professionals. In 2024, a total of 216 special health examinations were conducted, and no employees were classified as Level 3 or higher for health management.

▼Special health examination classification in the past 3 years(unit: number of people)

| Year | Total number of people tested | First-level health manager | Second-level health manager | Third-level health manager | Fourth-level health manager |

|---|---|---|---|---|---|

| 2020 年 | 349 | 275 | 74 | 0 | 0 |

| 2021 年 | 295 | 238 | 56 | 0 | 1 |

| 2022 年 | 241 | 183 | 54 | 0 | 4 |

Note:

- Level 1 management: Individuals who have been determined to have no abnormalities based on the consolidated results of the examinations.

- Level 2 management: Individuals who have been determined to have abnormalities that are not work-related based on the consolidated results of the examinations.

- Level 3 management: Individuals who have been determined to have abnormalities based on the consolidated results of the examinations, but job relevance cannot be determined and need to be rearranged for an assessment by an occupational medicine specialist.

- Level 4 management: Individuals who have been determined to have abnormalities that are work-related based on the consolidated results of the examinations.

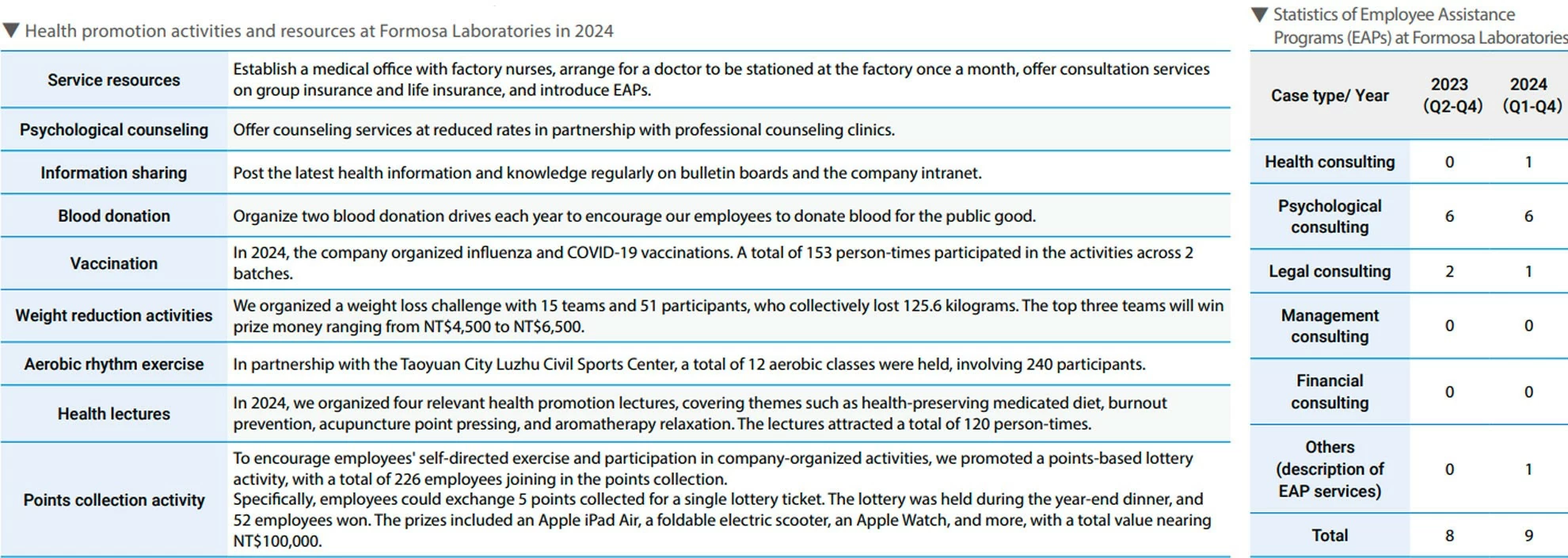

A Healthy Workplace

To help employees achieve a balance between work, health, and life, Formosa Laboratories launched Employee Assistance Programs (EAPs) in March 2023. In partnership with professional management firms and counseling centers, the company combines internal and external resources to support employees in adapting to work, managing organizational relationships, and handling personal emotional stress.

The program offers comprehensive support in areas such as medical consulting, psychological counseling, work management, finance, taxation, and legal concerns, fostering a caring and supportive work environment. Additionally, based on health examination results and employee needs, annual health promotion activities are organized to enhance the implementation of a healthy workplace. The Health Promotion Seal, certified by the Health Promotion Administration, Ministry of Health and Welfare (HPA), is set to be renewed successfully in 2024.