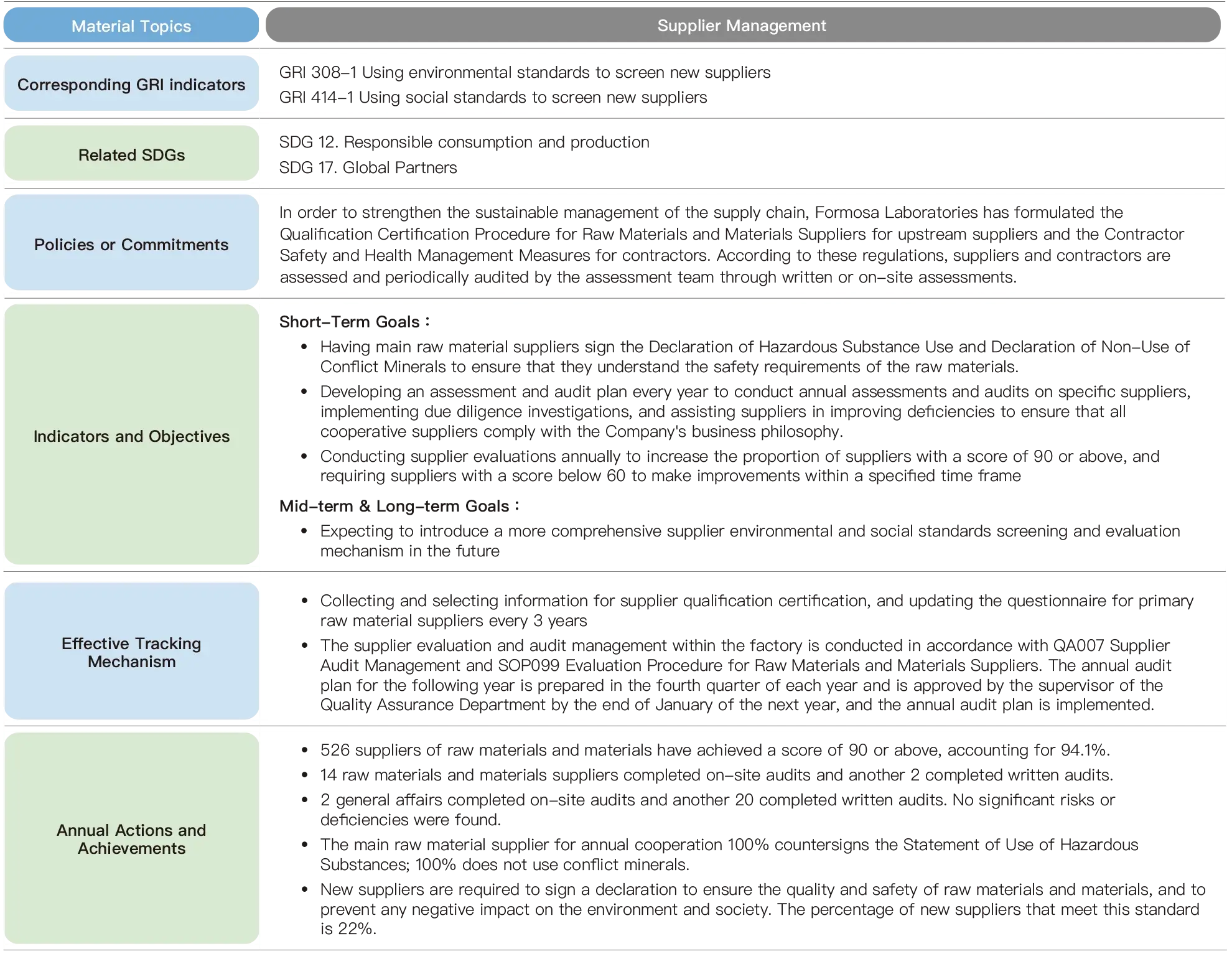

Formosa Laboratories 2022 Material Topic: The Management of Supplier Management

FORMOSA

FORMOSA

Supplier Risk Assessment

Formosa Laboratories requires its main raw material suppliers to sign a Declaration of Hazardous Substance Use and a Declaration of Non-Use of Conflict Minerals in order to disperse risks and continuously improve the overall quality of the supply chain. This policy is incorporated into the necessary items of supplier procurement management through the internal SOP for the Supplier Qualification and Assessment Certification Procedure. The main raw material suppliers are required to commit that their supplied products or components, corporate governance, and worker rights protection are in line with the Company's ESG management philosophy.

Formosa Laboratories actively assists and guides suppliers who fail to meet the Company's requirements in implementing improvement plans, while also implementing improvements in employee health and safety, human rights, and corporate social responsibility. If there is a violation of relevant regulations, the Company may assert termination or dismissal of the contract, and is committed to reducing supply chain risks and promoting supplier partners to jointly enhance corporate social responsibility.

| Environmental Risks |

|

|---|---|

| Social Risks |

|

Note: Main raw materials means raw materials that can form the main structure of the product (API).

In addition, Formosa Laboratories will continue to request new suppliers to sign relevant statements and declarations to ensure that the quality and source of raw materials and materials comply with safety standards, do not contain harmful substances that are restricted, and will not have a negative impact on the environment or society. The number of new suppliers signed in 2022 is 22, accounting for 22% of the total number of new suppliers that year.

In addition to the requirement of signing a declaration with suppliers, the Company expects to include environmental protection, labor conditions, occupational health and safety, human rights, and other related issues in the assessment through supplier questionnaires, evaluations, and audits. More comprehensive screening criteria will be introduced and a supplier evaluation system will be established as part of the Company's supplier management policy to enhance our corporate social responsibility.

Supplier Evaluation

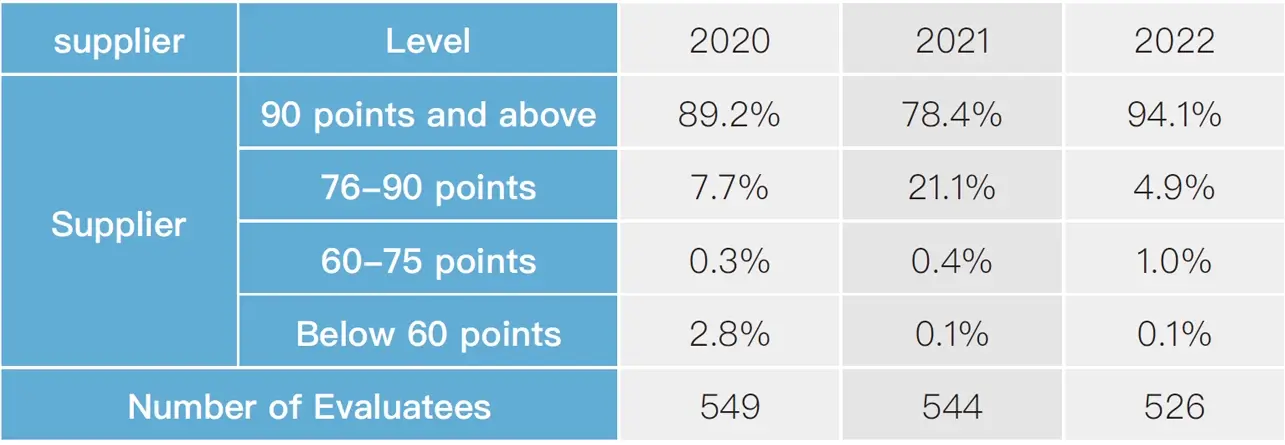

Formosa Laboratories conducts supplier evaluations based on SOP 099 Raw/Supply Material Supplier Evaluation Procedure and Materials by the Procurement Department. A supplier evaluation form is designed annually in the first quarter of the following year based on the quality and delivery records and the service attitude from the previous year. Through communication and visits with suppliers and contractors, we learn about the status of their compliance with regulations to ensure the proper implementation of laws and regulations. In addition, the Company also conducts annual evaluations of raw materials and materials suppliers, with scoring criteria divided into four categories: 90 points and above, 76-90 points, 60- 75 points, and below 60 points. If a supplier's score on the evaluation form is below 60 points, they will be required to make improvements within a specified period. If it is confirmed that they are unable to make concrete improvements, their application may be cancelled and their name removed from the list of qualified suppliers.

Based on the degree of impact on operations, we have adjusted the weightings of the supplier evaluation items.

In 2022, the Company's supplier evaluation items and weightings include: quality assurance 70%, delivery stability 10%, and service 20%. The supplier evaluation results for Formosa Laboratories in the past 3 years are as follows:

Formosa Laboratories Supplier Evaluation Results in the Past 3 Years

Note: The statistics are rounded, so there may be some errors in the calculations.